Design Preparation

How to Create Best Design for Printing

It is fairly important to generate press ready design file with correct parameters to ensure all are contents are inline.

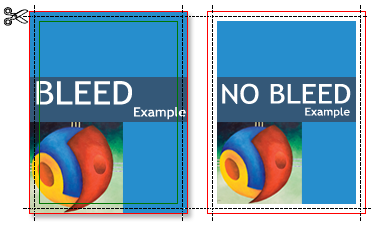

Use of Bleed: It is best to use at-least 3mm bleed in your design on all cutting / crease sides to ensure fully printed edges without any white or not printed area left.

Avoid up’s: Once submitting your artwork do not send file with up’s settings as this is adjusted during production.

Avoid Missing: Most of the times designers use certain fonts in the artwork, all used fonts need to be outlined/curved/grouped to avoid having missing fonts error once file is processed for pre-press

Color Conversions: Computer uses RGB color types whereas offset printing is done with CMYK type coloration. There is little difference in both of those, RGB colors are more bright compared to CMYK colors. It is best to have your artwork converted to CMYK to check color changes.

Final Checklist Before submitting your artwork:

- Use correct size artwork not stretch or squeezed

- Avoid design up’s

- Use correct internal and external bleed

- Use CMYK or PMS Colors

- Die Line must be provided in flat sized

- Dark black must use C =100%, M = 100%, Y = 100%, K = 100%

- All black must use black C =20%, M = 20%, Y = 20%, K = 100%

- All fonts and links should be embedded

- Lines of your artwork should be at-least 0.3pt and all text should be at least 8pt using a non-narrow, non-ultra light style font.

- Use at-least 5mm wide border

- All images should at-least be 300dpi at 100% resolution

- Press ready file must have trim marks

Printable File! Not Sure? If you are not sure about your file resolution or details email us and we should be able to help you in checking or editing your file. sales@bestofprinting.com

- GOOD: TIF or EPS files .

- BAD: JPEG/JPG or GIF